PROCEDURE

ON BIOGAS POWER PLANT ACCEPTANCE TEST AND PERFORMANCE ASSESSMENT FOR FEED-IN TARIFF

(FiT) PROJECTS IN MALAYSIA

SUSTAINABLE ENERGY DEVELOPMENT AUTHORITY (SEDA) MALAYSIA

2013

FOREWORD

The enforcement of the Renewable Energy Act 2011 [Act 725] on 1st December 2011 has enabled the Feed-in-Tariff (FiT) mechanism to be implemented in Malaysia paving for a sustainable for Renewable Energy (RE) growth trajectory for the RE Industry in Malaysia including solar photovoltaic, small hydro, biomass and biogas. All RE resources have shown promising development and it could be seen from the number of projects which has benefited from the FiT mechanism.

Biogas is defined as a gas produced by the anaerobic digestion or fermentation of indigenous organic matter under anaerobic conditions including but not limited to manure sewage sludge municipal solid waste and biodegradable waste originating from Malaysia. Biogas technology refers to systems that designed to turn organic waste products into usable energy. SEDA Malaysia, being the agency responsible for facilitation of RE growth is playing its role to ensure installations especially those under the FiT mechanism meet and complying to the international standards in terms of quality, reliability and safety which will indirectly impact the performance of the biogas power plants.

Eqn.16

Eqn.17

Eqn. 19

Eqn.18

Eqn.20

Eqn.21

Eqn.22

The Procedure on Biomass Power Plant Acceptance Test and Performance Assessment for FiT is prepared to provide assistance to the Feed-in Approval Holders (FiAHs) under the biogas category. The scope of this Procedure is relevant to biogas resources which refer to the Municipal Solid Waste (MSW), sewage treatment plant, energy crops, landfills and Palm Oil Mill Effluents (POME). This Procedure is useful when preparing the plant performance assessment and for continuous performance assurance reporting by the biogas project developers in preparing test report for FiT Commencement Date (FiTCD). The test report is important as it will be used to determine the expected performance of the biogas power plants.

I would like record my deep appreciation to Malaysia Palm Oil Board (MPOB), Energy Commission, Tenaga Nasional Bhd (TNB), developers and technology providers who has deliberated exhaustively and contributed in giving inputs in the process of preparing the Procedure.

Lastly, I would also like to thank Energy Institute Malaysia for assisting SEDA Malaysia develop the Procedure on Biogas Power Plant Acceptance Test and Performance Assessment which will be an important document for use by the RE industry players.

Datin Badriyah Hj Abdul Malek

Chief Executive Officer

Sustainable Energy Development Authority Malaysia

TABLE OF CONTENTS

No | Contents | Page No. |

4.4.2.4 | Sample Filter | 28 |

4.4.2.5 | Sample Pump | 29 |

4.4.2.6 | Flow Control and Measurement | 29 |

4.4.3 | Emission Measurement and Analyzer | 29 |

4.4.4 | Instrument Operating Procedure | 30 |

4.4.5 | Engine Emission Measurement Procedures | 31 |

4.4.6 | Emission Testing Frequency and Compliance | 32 |

4.4.7 | Safety and Health Precautions | 32 |

4.5 | Fuel Sampling and Analysis | 33 |

4.5.1 | General guideline for sampling of biogas | 33 |

4.5.2 | Reference Procedure for Biogas Sample Collection | 34 |

4.5.2.1 | Safety and Health Considerations | 35 |

4.5.3 | Reference procedure for Sample Analysis | 35 |

4.6 | Calibration of Test Instrumentations | 35 |

5 | Reference Test Conditions and Corrections | 36 |

5.1 | Reference Atmospheric Condition | 36 |

5.2 | Atmospheric Correction Factor | 36 |

5.3 | Alternative Fuels | 37 |

5.4 | Power Correction Factor | 37 |

5.5 | Method of Power Correction | 37 |

5.6 | Other Types of Engine | 39 |

6 | Test Data And Result Analysis | 40 |

6.1 | Reciprocating Gas Engine | 40 |

6.2 | Chemical Energy Input or Heat Consumption Rate | 41 |

6.3 | Energy Output and Losses or Heat Rate Calculations | 41 |

6.4 | Thermal efficiency Calculation for Reciprocating Engine | 42 |

6.5 | Air Fuel Ratio and Equivalence Ratio | 42 |

6.6 | Input Data Required for Reciprocating Engine Performance | 43 |

7 | Performance Results Assessment’s | 45 |

8 | List of References | 46 |

9 | List of Appendix | 48 |

LIST OF FIGURES

Figure No. | Title | Page No. |

1 | Gas Engine unit with Generator Set | 8 |

2 | Example of OEM Data Fuel Consumption versus Brake Power | 11 |

3 | Effects of Hydrogen Sulphide (H2S) on People | 16 |

4 | Typical air flow at both in and out of the engine room | 17 |

5 | Typical Horizontal Exhaust System | 18 |

6 | Minimum Number of Traverse Points | 24 |

7 | Example of the Location of Traverse Points | 26 |

8 | Example of Continuous undiluted exhaust gas analysis system | 27 |

9 | Example of Typical NDIR Analyzer Response Curves | 30 |

10 | Sample of Barbed Screw Lock | 34 |

11 | Energy Balance for a Reciprocating Gas Engine | 40 |

LIST OF TABLES

Table No. | Title | Page No |

1 | FiAH Performance Assessment Criteria for Acceptance and Reliability Test Run for Biogas Plant | 10 |

2 | Accuracy of Measuring Instruments | 20 |

3 | Minimum Number of Traverse Points for Sampling Sites that meet the Eight- and Two- Diameter Criteria | 24 |

4 | Location of Traverse Points in Circular Stacks – Percentage of Stack Diameter from Inside Wall to Traverse Point | 25 |

5 | Recommended minimum filter loading | 29 |

6 | Typical Ranges and Accuracy of Analytical System | 29 |

7 | Required Calibration and Span Gases Composition | 31 |

8 | Biogas Fuel Properties | 33 |

9 | Test Methods for Biogas Fuel Properties | 35 |

10 | Reference Atmospheric Condition | 36 |

11 | Results Assessments | 45 |

DEFINITIONS

Gas Engine | An engine in which the fuel in its natural state is a gas and the air-fuel mixture is ignited by spark or compression ignition within the combustion chamber or the pre-chamber |

Intercooler | A device used to cool the intake air after it leaves the turbocharger compressor but before it enters the engine cylinder. This device sometimes called an after cooler or charge air cooler |

Naturally Aspirated | A term used to describe an engine which does not use a device to increase the pressure on the intake air of the engine before it enters the cylinder |

Turbocharger | A rotary air compressor driven by a turbine using exhaust gas as the driving fluid and compressing intake air into the engine |

Four Stroke Cycle Engine | An engine completing one cycle in four strokes of the piston or two shaft revolutions |

Two Stroke Cycle Engine | An engine completing one cycle in two strokes of the piston or one shaft revolutions |

Heating Value | The energy liberated when a unit mass of the fuel completely oxidized and the temperature of reactants is equal to the products |

Equivalence Ratio | A ratio of the actual fuel-air ratio (f/a) divided by the chemically correct (stoichiometric) fuel-air ratio |

Rated Engine Speed | Engine speed corresponding to the declared power |

Declared Power | Value of the power declared by the manufacturer which engine can deliver under a given set of circumstances |

Reference Test Conditions | The standard (reference) engine inlet air supply and inlet fuel conditions to which all power corrections are made |

Exhaust Emission | Any substance(but normally limited to pollutants) emitted to the atmosphere from any opening downstream form the exhaust port of the combustion chamber of an engine |

Steady State Condition | An engine operating condition at a constant speed and load and at stabilized temperatures and pressures |

Calibration Gasses | A gas used to establish instrument response, Concentration known ±2%, traceable to National Institute of Standards and Technology Standards Reference Materials |

Span Gas | A gas used routinely to check instrument response, Concentration traceable to calibration gas |

Zero Gas | A pure gas such as nitrogen or air used to determine the zero point of an analyzer |

LIST OF ABBREVIATION

Symbol | Description |

pr | Standard reference total barometric pressure |

psr | Standard reference saturated water vapour pressure |

psy | Ambient saturated water vapour pressure during test |

py | Ambient total barometric pressure during test |

Pr | Brake power under standard reference condition |

Py | Brake power under ambient conditions during test |

q | Fuel mass per cycle per litre of engine swept volume |

qc | Fuel mass per cycle per litre of air available for combustion |

rr | Boost pressure ration under standard reference conditions |

Tr | Standard reference ambient air thermodynamic temperature |

Ty | Ambient air thermodynamic temperature during test |

αa | Power correction factor for spark ignition engines |

αc | Power correction factor for compression ignition engines |

Ør | Standard reference relative humidity |

Øy | Ambient relative humidity during test |

ηEff | Thermal efficiency based on net electrical power |

Qs | Heat Rate |

ENetCorr | Corrected Net Energy Output |

Hf | Heating Value of Fuel (Lower Heating Value) |

m | Moisture Content |

mf | Fuel Flow Rate |

ENet | Net Energy Output |

ELOSS | Total Energy Loss |

ETotal | Total Energy Output |

EHf | Total chemical Energy Heat Input |

αa & αc | Power Correction Factor |

fm | Engine Factor |

fa | Atmospheric Factor |

T | Ambient Pressure |

tx | Ambient Temperature |

CO | Carbon Monoxide |

CO2 | Carbon Dioxide |

O2 | Oxygen |

N2 | Nitrogen Oxide |

Symbol | Description |

NH3 | Ammonia |

RE | Renewable Energy |

POME | Palm Oil Mill Effluent |

MSW | Municipal Solid Waste |

SI | Spark Ignition Engine |

CI | Compression Ignition Engine |

AD | Anaerobic Digester |

FiT | Feed in Tariff |

OEM | Original Equipment Manufacturer |

REL | Rated Engine Load |

OD | Outer Diameter |

in | Inch |

m | meter |

mm | milimeter |

ppm | part per million |

NDIR | Non Dispersive Infrared |

PMD | Paramagnetic Detector |

CLD | Chemiluminescent detector |

HCLD | Heated Chemiluminescent detector |

F/A | Fuel Air Ratio |

ρfuel | Density of gases fuel |

ρair | Density of ambient air |

SAE | Society of Automotive Engineers |

ISO | International Standards Organization |

PTC | Performance Test Code |

ASME | American Society of Mechanical Engineering |

Vf | Fuel Flow Rate |

Va | Air Flow Rate |

Vexh | Exhaust Gas Flow Rater |

SEDA | Sustainable Energy Development Authority |

FiAH | Feed-in Approval Holder |

FAT | Factory Acceptance Test |

GFC-NDIR | Gas-Filter Correlation Non-Dispersive Infrared |

UVA | Ultra Violet Absorption |

UF | Ultraviolet Fluorescence |

FTIR | Fourier Transform Infrared |

PART 1 INTRODUCTION

The Feed in Tariff (FiT) is Malaysia’s financial mechanism under the Renewable Policy and Action Plan to catalyse generation of Renewable Energy (RE) up to 30 MW in size. The mechanism allows electricity produced from RE resources to be sold to power utilities at a fixed premium price for a specific duration to enable financial viability of RE plant development.

FiT rates had been introduced through Renewable Energy Act 2011 [Act 725] to promote RE technology in Malaysia. One of the RE technology which qualifies for FiT is biogas which abundantly available from waste resources such as Municipal Solid Waste (MSW), sewage water, energy crops and Palm Oil Mill Effluent (POME).

The most common approach to produce electricity from biogas is through gas engine either spark ignition (SI) or compression ignition (CI). It is because gaseous fuelled reciprocating is matured technology in terms of global manufactures supply and support efficient infrastructure. Moreover, this technology is more tolerant to biogas impurities and need less initial cost than other technology [1] [2]. Meanwhile, biogas is a renewable and sustainable energy carrier produced via Anaerobic Digestion (AD) in humid condition with absence of Oxygen or biological decomposing or organic matter in landfills. Biogas mainly consists of Methane (40-75%), Carbon Dioxide (20-45%) and some other compounds [3]. The compositions of biogas vary from one source to another and also depend on condition of the digester or the landfill.

In reciprocating engine, the combustion occurs in enclosed combustion chamber where the thermal energy that generated due to combustion expand and converted into mechanical energy by rotating the crankshaft which is coupled with generator to produce electricity. Figure 1, shows the typical biogas fired gas engine power plant.

This procedure shall provide the methodology for Feed-in Approval Holder (FiAH) to carry out performance assessment of a biogas fired gas engine power plant to be qualified for FiT commencement accordance RE Act 2011.

Figure 1: Gas Engine unit with Generator Set

PART 2 PLANT PERFORMANCE ASSESSMENT

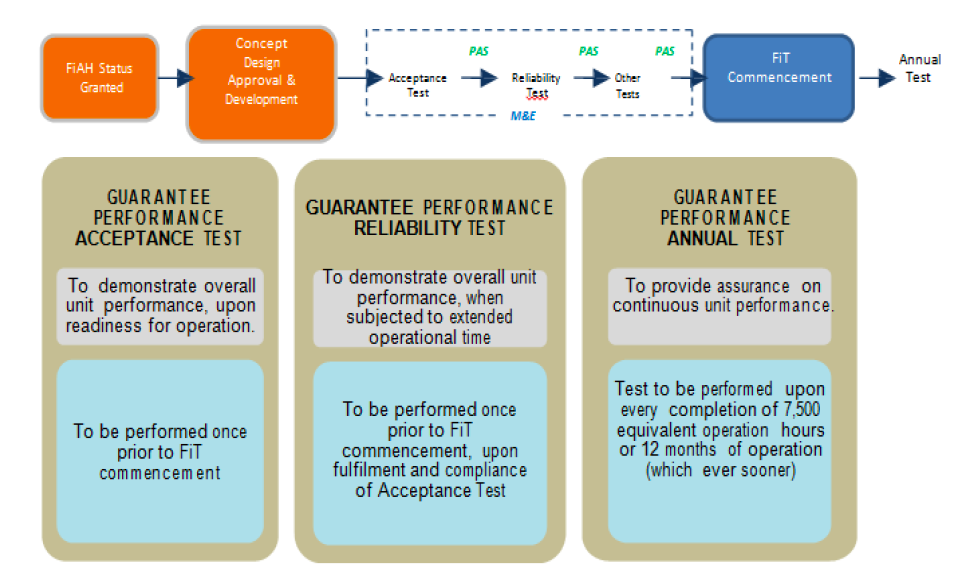

According to the Guidelines and Determinations of the Sustainable Energy Development Authority Malaysia (SEDA Malaysia) (rev Feb 2013), Acceptance Tests and Reliability Test must be carried out in respect of all renewable energy installations. The Subparagraph 15(1)(a)(i) of the Technical and Operational Requirements Rules requires the submission by FiAH to the distribution licensee and the Authority of a certificate from a qualified person stating that the renewable energy installation and interconnection facilities have been designed, constructed, installed and tested in accordance with prudent utility practices. In addition, according to Subparagraph 8(a) of Third Schedule to the Technical and Operational Requirements Rules requires the submission by the FiAH to the distribution licensee and the Authority of a certificate from a qualified person stating that the renewable energy installation has successfully completed a Reliability Run.

2.1 Performance Assessments

All new plants that have been granted FiAH status must be subjected to Acceptance Test and Reliability Test, prior to FiT commencement. The overall performance assessment is as follows;

Legacy plant previously under the Renewable Energy Power Purchase Agreements (REPPAs) is not required to undertake the Acceptance Test and Reliability Test prior to FiT Commencement. However, if the plant is claiming for any upgrades in its performance efficiency, a set of Acceptance Test and Reliability Test must be conducted to verify the claim. Otherwise, only Guarantee Performance Annual Test shall be performed to demonstrate the guaranteed efficiency or to apply for new efficiency bonus.

2.2 Key Performance Indicators

The key performance indicators listed in Table 1 shall be assessed during the performance assessment;

Table 1: Performance Assessment Criteria for Acceptance

No | Indicator | Qualification Criteria | Frequency of assessment |

Acceptance Test | Reliability Test | Annual Test |

Reciprocating Gas Engine |

1 | Energy Input | Must be reported | | |

2 | Energy Output | Must be reported | | |

3 | Efficiency | Minimum of 40% for Bonus Eligibility | | | |

4 | Shaft Speed | Must be reported | | |

5 | Air, Fuel Flow and Exhaust Flow | Must be reported | | |

6 | Ambient Reference Condition | Must be reported | | |

7 | Biogas Fuel Properties | Must be reported | | |

8 | Flue Gas Emissions | Compliance to Environmental Quality (Clean Air) Regulations, 1978 | | |

And Reliability Test for Biogas Plant

PART 3 PERFORMANCE ASSESSMENT GUIDELINE

3.1 Scope Of Assessment

3.1.1. Gas Engine Unit

Performance Test to be carried out with reference to SAE International standard for Engine Power Test Code (SAE J1349) for Spark ignition and Compression ignition engine and its supplementary codes. The parameters to be assessed are:

a. Energy Input (LHV – Biogas)

b. Energy Output (Power Meter)

c. Shaft Speed

d. Exhaust Gas Temperature and Back Pressure

e. Ambient air temperature and pressure (Barometric)

f. Fuel temperature and Mass of fuel consumption

g. Flue gas and plant emission

3.2 Test Requirements

3.2.1. The rated capability

The rated capability of the unit must be specified prior to testing. The followings are recommended rated capability parameters, which shall be provided by the OEM.

a. Net Brake Power and Torque

b. Rated Net Power and Torque

c. Rated Power Speed (Power vs Speed)

d. Friction Power

e. Engine Inlet Pipeline Pressure Drop versus Air Flow Rate

f. Generator Output versus Engine Inlet Temperature

g. Heat Rate versus Engine Inlet Temperature

h. Ambient Pressure and Site Altitude Correction Curve.

Figure 2, shows the typical OEM data fuel consumption versus observed brake power at specific speed.

Figure 2: Example of OEM Data Fuel Consumption versus Brake Power

(Source: Rosaler, 2002)

3.2.2 Minimum test runs and test durations

a. For Acceptance Test and Annual Test, the engine shall be run at no less than three (3) loads and one which shall be full load.

b. The engine shall be run at equally spaced load interval as give below :-

50% REL (Rated Engine Load)

75% REL

100% REL

Each test run will be conducted twice and two sets of reading shall be taken for each load. Each test run shall be conducted for minimum four (4) hours.

c. For Reliability Test

Test run shall be performed once at 100% REL.

Test shall be conducted for a minimum of 300 hours duration (approximately for 14 days, 24 hours operation, 90% uptime)

3.2.3 Frequency of data recording/ measurements

a. All readings shall be taken once load and speed measurements have remained stable within 1% and controlled temperatures have remained stable within ±2 °C for at least 1 minute.

b. It is recommended that automatic data recording system to be used and data recorded at no more than 15 seconds intervals.

c. The recorded measurements shall be the average of readings over a span of 1 minute.

3.3 Test Preparation

All FiAHs shall first ensure the provision and ports for measurements are incorporated in the plant design and development stage to enable data collection during performance verification and annual certification. Prior to test commencement, a review of the required documents inclusive of the Process and Instrumentation Diagrams (P&IDs) for the plant and system is required. The followings pre-test checklist shall also be performed:

a. Complete list of all equipment to be subjected to the test and its respective performance guarantee values at installation. The historical data on present operating conditions of equipment and operating hours logged must be established.

b. Establish specific test procedures, with reference to this guideline. Procedures shall explicitly describe any exceptions.

c. Prepare a complete test datasheet containing parameter to be measured, methods of measurement and instruments to be used shall be established with reference to this guideline

d. Establish performance analysis procedure, with reference to this guideline.

e. Check for calibration record of all instruments to be used for measurement. All equipment shall be calibrated prior to testing. . The valid calibration certificate, not more than six months old, conforming to internationally recognized calibration standards, for all the instruments installed in the field and used as portable along with the traceability should be available for verification prior to test.

f. Check that typical test data logged automatically in all data-logging system

g. Establish specific time duration for each test and minimum number of tests.

h. Check all operating parameters under which the performance needs to be evaluated, for each equipment in the system.

i. Prior to the test, it shall be ensured that the intended fuel is being used as the as-fired fuel and the amount of the fuel is sufficient for entire test.

j. Prepare list of personnel assigned for data measurement/recording throughout the test and also check sufficient amount of lubricants and coolants are provided to support the test.

k. It is also essential to obtain the performance, losses and correction curves data, generally supplied by the respective original equipment manufacturer (OEM).

3.3.1 Preliminary Test Run

a. Preliminary Test Run shall be conducted by unit operator prior to each test run.

b. During preliminary test run, the unit must reach its stabilization at its rated capacity output as specified by the engine manufacturer.

c. Upon reaching stabilization, three sets of readings must be taken for all data to ensure all system are operating at basic design conditions and all the measurement instruments are functional.

3.3.2 Stabilization period

Unit shall operate at the test load conditions for a minimum of 2 hours before beginning of each measurement to ensure stable conditions and the engine speed shall not deviate from the selected speed by more than ±1 % or ±10 min-1, whichever is greater.

3.3.3 Test Operating Conditions

a. Steady State Conditions

The engine must be started and warm up accordance with the manufacturer’s recommendations prior to test.

Gas Engine must reach steady state condition before it is subjected to test load and measurements.

To ensure equilibrium is reached, the unit shall have been in continuous operation of firing test fuel for minimum of 2-hours or engine speed and torque remained stable within ±1% at least for 1 minute before acquiring the measurement.

Operation data such as brake power, fuel flow air flow, exhaust mass flow and inlet air temperature shall be taken simultaneously and the readings should be the average of at least two stabilized consecutive readings.

The permissible deviation for each individual measurement shall be kept within the permissible range throughout the test as described in Appendix 1.

All measuring instruments and apparatus used during tests shall be tested and calibrated for every 12 months except for gas flow for every six (6) months or periodically at the time intervals specified by the engine manufacturer.

Only interruptions due to maintenance as given in working manual is permitted during test while other interruptions occurred due to defect in the engine then the entire test need to be repeated.

3.3.4 Operation and control

a. Plant must be ensured to operate closest to the design cycle operation with permissible bias as listed in Table 2, for the basis of performance guarantee.

b. Prior to testing, all relevant plant automatic control systems are to be set, function effectively to achieve the required values and stability.

3.3.5 Pre-Test System Checks

a. Plant system checks are to be made with the unit operating on the design cycle, at nominally full load and terminals conditions to be held as close as possible to specified values. Plant shutdown for pre-test check may takes up to five days duration (shorter or longer, subjected to plant condition). The followings are pre-test checks:

Visual inspection for leaks and loose fasteners

Checking engine pre-lubrication system

Inspect lubrication oil level and ensure the lubrication oil is changed according to schedule maintenance

Check oil filters and fuel filters condition, make sure the filters are replaced according to schedule maintenance

The heat exchanger for lube oil and engine jacket cooling water need to be clean at an interval of 500 hours (Depends on water quality check with manufacturer recommendation)

Check fuel injectors and clean if choked foreign materials

Check the water pump working properly

Ensure the data acquisition system able to retrieve data from sensors (If applicable)

Ensure spark plugs are changed according to schedule maintenance

3.3.6 Standard Production Equipment (SPE)

Equipment and auxiliaries to be installed for the test to determine engine power accordance to SAE J1349 (2011). Refer Appendix 2.

3.3.7 Test Manning Plan

a. SEDA Malaysia, Distribution Licensee or its appointed representative shall be presented to witness the conduct of performance assessment. Notification shall be given to the respective authorised personnel at minimum fourteen (14) days prior to performance assessment commencement.

b. The followings personnel shall be presented during test:

Plant Engineer

Overall test controller

Gas engine operations engineer

Test electrical engineer

Test instrumentations technician

Fuel gas analysis team

Third party verifier for flue gas analysis (Optional)

Engine Manufacturer (Optional or If included in Purchase Agreement)

Observers for manual readings

Other personnel as needed

b. List of presented personnel must be included in the test report.

3.4 Biogas Safety and Handling Considerations

This guideline does not address all of safety concerns associated with biogas plant. It is responsibility of the user of this guideline to ensure appropriate equipment is installed to ensure safe and avoid possibility of any explosion in plant. The main safety hazards with biogas include explosion, asphyxiation and hydrogen sulphide poisoning. Figure 3.0, shows the health effects of Hydrogen Sulphide (H2S) to human. Meanwhile the following factors are recommended for biogas plant operation/installation.

Flame arresters should be installed 5m upstream of all possible ignition sources and thermal shut-off valve should be used in conjunction with all in line arresters to provide additional protection by shutting valve off the gas source to the flame.

It is important to check with local building codes and Occupational Health and Safety Association (OSHA) standard and fire protection codes when determining installation site for waste gas burner or enclosed flares and its related equipment.

Regular inspection is recommended for pressure and vacuum relief devices and flame arresters to ensure proper operation.

All diaphragm operated valves, manometers and other devices which might vent gas located indoors should have provision for vent lines terminating outside the building.

All equipment must be in well ventilated areas and entering confined spaces should be avoided without verifying the absence of H2S.

Installation of methane and hydrogen sulphide gas detector in biogas plant is compulsory to detect any gas leaking.

Figure 3.0: Effects of Hydrogen Sulphide (H2S) on People

(Source: Bothi, 2007)

3.5 Recommended Installation and Maintenance for Biogas Gas Engine

This guideline mainly emphasised on performance assessment of biogas gas engine plant accordance international standards. Nevertheless, this section has highlighted few important elements to be considered for biogas plant installation and maintenance. Thus, all FiAHs are recommended to consider all these elements prior to design and construction of biogas plant.

3.5.1 Location of Equipment

The engine installation should be designed with maintenance requirements in mind. For example, serviceable components such as filters, fittings and connections should be readily accessible to the engine operator for easy access to the engine to perform maintenance activities and daily equipment checking. Moreover, sufficient service space on all sides of the engine will allow easy removal of engine parts and overhead crane should be incorporated into the engine room design to assist the mechanic operator in removing heavy assemblies. Besides that, air line connections will be necessary to use air tools. Appendix 5, shows typical envelope dimensions for gas generator set. Minimum clearance on all sides is also chartered and can be used for preliminary space estimates.

3.5.2 Ventilation

In engine generator installations sufficient airflow must be provided into the engine room for ventilation and combustion air. It is also good practice to calculate the amount of heat transferred to the room air (etc. engine and generator radiator heat, plus any other heat sources) to determine the temperature rise of the engine room air. In many cases it is necessary to increase the engine room air flow to maintain at reasonable operating temperature. The following are general “rule of thumb values” that assume only radiating heat source in the engine room is the engine-generating set.

a) Cubic feet per minute of air required to limit air room temperature rise to (10°C), over normal ambient = 45 x kilowatt rating

b) Cubic feet per minute of combustion air required = 2.4 x kilowatt rating for gas engine

Thus, the total air requirement is equal the sum of (a) and (b). Meanwhile, other ventilation considerations are filters for sandy or dusty areas and louvered openings at both inlet and outlet air openings. Figure 4, shows the typical air flow at both in and out of the engine room.

3.5.3 Exhaust System

Ensure the exhaust system has been designed to expel out exhaust gasses safely outside area, consistent with all local building and environmental codes. Do not discharge gasses near windows, ventilation shafts or air inlets. The exhaust outlet must be designed to keep out water, dust and dirt. Roller type supports and flexible exhaust connections should be used to absorb thermal expansion. A condensate trap and drain should be designed into exhaust system and the drain should be in an easy to reach location. The exhaust system back pressure should be checked periodically and the back pressure must fall within the limits established the manufacturer. Figure 5, shows the typical horizontal exhaust system.

Figure 4: Typical air flow at both in and out of the engine room.

(Source: Rosaler, 2002)

Figure 5: Typical Horizontal Exhaust System

(Source: Rosaler, 2002)

3.5.4 Cooling System

Potential problems that associated engine cooling system can be avoided if the following considerations are incorporated into the design and installation of the cooling system:-

a) Excessive fittings, elbows and connectors in the piping system will impede coolant flow thus it’s recommended to reduce number fittings in the system.

b) Ensure the location of radiator away from wall or any other obstructions that cause air recirculation or restricts the flow. These obstructions would also include any dirt source, vehicle travel path, air-conditioning units or exhaust stacks and chimneys.

c) All filters fill points and bleed blocks should be installed in an easy to reach location.

d) An expansion tank balance line should be incorporated into the cooling system, running to the suction side of the water pump. This balance line will maintain a net positive suction at the inlet of the pump and reduce the possibility of air locks and cavitational erosion.

3.5.5 Air Induction System

Like other engines, accessibility is the key to air-induction system maintenance. The filter should be positioned at entrance to the air induction system and it can be easily remove or replace. Always locate the air inlet system away from concentrations of dirt, exhaust stack, fuel tank, tank vent, stockpile of chemical waste and industrial waste. The air duct should be sealed to avoid drawing dirty air in behind the filter and must be checked periodically for leaks. The air system ducting should be seamless, welded-seam or PVC piping. Flanged fittings with gaskets, not threaded connections should be used between pipe sections to avoid restrictions in the system. The best ducting system is as short as possible, use long-radius bends and low restriction fittings. Never allow air duct restriction tom exceed 2 in (50.8 mm) of water column. The air ducting system must be leak free under vacuum conditions.

3.5.6 Engine Alignment

The alignment of the engine mount and the alignment between the engine and the driven equipment are critical to long engine life. Alignment should be checked periodically according to the manufacturer recommendations.

PART 4 TEST INSTRUMENTATIONS AND DATA ACQUISITION

4.1 Measuring Instrumentations Bias Limits

Instruments to be used during test are recommended to have following accuracy tolerances.

Table 2: Accuracy of Measuring Instruments

No | Instruments | Accuracy | Calibration Intervals (Months) |

1 | Portable Tachometer (Speed) | ± 0.2 % | 12 |

2 | Inlet Air Temperature | ± 1.0 % or ± 2K | Refer 4.6(b) |

3 | Inlet Air Pressure | ± 0.10 kPa | Refer 4.6(b) |

4 | Inlet Air Flow Measurement | ± 0.25 % | Refer 4.6(b) |

5 | Biogas Temperature | ± 2.0 % or ± 2K | Refer 4.6(b) |

6 | Biogas Pressure | ± 0.5 kPa | Refer 4.6(b) |

7 | Biogas Flow Measurement | ± 0.25 % | 6 |

8 | Inlet Air Humidity | ± 1.0 °C Wet Bulb | Refer 4.6(b) |

9 | Exhaust Pressure | ± 0.5 kPa | Refer 4.6(b) |

10 | General Temperature Measurements | ± 2 °C | Refer 4.6(b) |

11 | Other Gasses Pressure | ±0.5 kPa | Refer 4.6(b) |

12 | Portable Power Meter | ± 0.25 % | 12 |

4.2 Recommended Test Instrumentation and Methodology

The followings are recommended test instrumentation and methodology for data acquisition:

4.2.1 Flow measurements

a. ISO 5167 can be as the guideline for flow measurement techniques, design, construction, location and installation of flow meters.

b. Test flow-meters shall be preserved its as-calibrated condition. This can be done by installation during unit shut down immediately before test and removal after unit shut down immediately after test

c. Test data measurement shall be conducted in accordance to PTC19.5 (R2004) - Supplementary Code on Instruments & Apparatus for Flow Measurements

d. Recommended instrumentations:

Gaseous Fuel – Volumetric Flow Meter

Air and Exhaust Flue Gas flow (for velocities > 3 m/s and for temperature up to 7000C) - Calibrated pitot tube/manometer.

Air and Exhaust Flue Gas flow (for velocities ≤ 3m/s) – calibrated anemometer.

Sampling Grid for obtaining flow measurement along stack or duct can be established using guidelines in the following section

4.2.2 Pressure measurements

a. Test data measurement shall be conducted in accordance to PTC 19.2 - (R1998) - Supplementary Code on Instruments & Apparatus for Pressure Measurement

b. Recommended instrumentations:

Differential pressure across each flow-meter - Calibrated differential pressure transducers

Fuel pressure – high accuracy calibrated pressure transducers

Exhaust pressure – calibrated absolute pressure transducers

Gas pressure – calibrated U-tubes or test manometers

Atmospheric pressure – calibrated precision barometer

For measurement of low pressures ≤0.2 MPa (absolute), manometers can be used.

c. Recommended instruments location accordance to SAE J1349 (2011) and ISO 15550(2002) :

Inlet air – Shall be measured at the entrance to the engine air induction system and this measurement shall be made within 0.15m of the entrance to the air induction system inlet duct.

Intake manifold – Shall be measured at as static value with probe located in a section common to several cylinders.

Charge air cooler – The pressure probe should be located at the inlet and outlet of the charge air cooler.

Oil pressure – The oil pressure shall be measured at the entrance to the main oil gallery.

Exhaust pressure – The exhaust back pressure shall be measured at a point at least three pipe diameters downstream from the outlet flange of the exhaust manifold and downstream at the turbocharger (if applicable).

Fuel pressure – Shall be measured at outlet of the volumetric flow meter for gaseous fuelled engines.

4.2.3 Temperature measurements

a. Test data measurement shall be conducted in accordance to SAE J1349 (2011) and ISO 15550 (2002).

b. Recommended instrumentations:

Electrical methods – Resistance thermometer or thermocouple with measuring apparatus

Fluid type thermometers

c. Recommended Instruments location :

Inlet air – Shall be measured at the entrance to the engine air induction system and this measurement shall be made within 0.15m of the entrance to the air induction system inlet duct.

Intake manifold – Shall be measured at as static value with probe located in a section common to several cylinders.

Charge air cooler – The thermocouple probe should be located at the inlet and outlet of the charge air cooler.

Oil temperature – The oil pressure shall be measured at the entrance to the main oil gallery.

Exhaust temperature – The exhaust back pressure shall be measured at a point at least three pipe diameters downstream from the outlet flange of the exhaust manifold and downstream at the turbocharger (if applicable).

Fuel temperature – Shall be measured at outlet of the volumetric flow meter for gaseous fuelled engines.

Coolant temperature – Coolant temperature in liquid cooled engines shall be measured at the inlet and outlet of the engine and air cooled engines at points specified by the manufacturer.

Similar equipment

4.2.4 Electrical power measurements

a. Calibrated portable power analyser shall be connected to the installed transformer to measure total output at the high voltage terminals of the main transformer

b. In case of existence of any external tap between the generator and the point of measurement, supplementary metering of equivalent accuracy may be provided to determine the total generator output.

c. The ASME PTC 19.6 “Electrical Measurements in Power Circuit” or equivalent standard test code shall be used for detailed instructions for measurement of electrical quantities

d. Recommended instrumentations:

AC Generators – single-phase watt-hour meter to be used in each phase to determine power output

DC Generators – DC-ammeters and DC-voltmeters

e. All power measurement instrument accuracy shall be at least ± 0.25% or less accuracy and valid calibration certificate of portable analyser must be reported in acceptance and annual report.

4.2.5 Measurement of Time

The measurement of time of test durations and other observations can be determined by observations of synchronized stop watches by the individual observers. Watches and clocks can be synchronized at the start of the test with the plant data and instruments.

4.3 Air Flow, Exhaust Flue Gas Flow And Temperature Sampling Grid

The following methodology provides guideline for establishing sampling grid at the stack/ duct.

a. Measurement Site

Select a site in a straight section of stack or duct located at least eight stack or duct diameters downstream and two stack or duct diameters upstream of any flow disturbance such as a bend, expansion, contraction, visible flame, junction, or stack exit.

In the case of rectangular stacks or ducts, an equivalent diameter (De) shall be used in determining the downstream and upstream distances.

Where,

L = stack length

W = stack width

In circular stacks or ducts, at least two sampling ports with a 90° separation are required. For particulate traverses, one diameter should be in the plane of an upstream flow disturbance.

For rectangular flow areas, ports are located on the most accessible face of the duct. The number of ports will be determined by the total number of traverse points.

b. Number of Traverse Points

The required minimum number of traverse points for a circular or rectangular cross section is determined from Table 3.

When the eight- and two-diameter criteria cannot be satisfied, the minimum number of traverse points is determined from Figure.6

Determine the number of diameters upstream and downstream from the sampling site to the flow disturbances. Then using Figure 6, determine the minimum number of traverse points corresponding to (a) the number of duct diameters upstream, (b) the number of duct diameters downstream.

Select the higher of the minimum numbers of traverse points from (a) and (b). In the case of circular cross sections, if the required number of points does not equal a multiple of four then the required number of points must be increased to the next greater multiple of four

Table 3: Minimum Number of Traverse Points for Sampling Sites that meet the Eight- and Two-diameter Criteria

(Source: ASME PTC 19.10)

Stack or Duct Diameter (m) | Required Minimum Number of Traverse Points |

Circular Duct | Rectangular Duct |

> 0.61 | 12 | 12 |

0.30 to 0.61 | 8 | 9 |

Figure 6: Minimum Number of Traverse Points

(Source: ASME PTC 19.10)

c. Location of Traverse Points

For stacks or ducts with a circular cross section, locate the traverse points according to Table 4. These points are located at the centroid of equal areas of the cross section

The minimum distance between the stack wall and a traverse point shall be 2.5 cm (1.0 in) for stacks with diameters greater than 0.61 m (24 in) and 1.3 cm (0.5 in) for stacks with diameters less than 0.61 m (24 in)

For rectangular cross sections, the area is divided into as many equal rectangular sections as there are sampling points

Locate the traverse points at the centroid of these rectangular sections.

The cross-sectional layout of a rectangular duct shall be chosen such that the ratio of the length to the width is between 1.0 and 2.0

Table 4: Location of Traverse Points in Circular Stacks - Percent of Stack Diameter from Inside Wall to Traverse Point

(Source: ASME PTC 19.10)

An example of the location of traverse points for a circular and rectangular stack is illustrated in Figure. 7.

Figure 7: Example of the Location of Traverse Points

(Source: ASME PTC 19.10)

4.4 Emission Sampling and Analysis

4.4.1 Introduction

The flu gas analysis shall be conducted accordance to SAE recommended practices J177 (95), J254 (93), J1003 (95) and ISO 8178-1(1996). The flue gas analysis concentrates on the measurement of the following components such as carbon monoxide (CO), carbon dioxide (CO2), oxygen (O2), sulphur dioxide (SO2) and nitrogen oxides (NOx). All measurements are measured during steady state condition. In addition, the emission test must be carried accordance to reference test conditions and corrections (Refer Section: 5).

4.4.2 Emission Sampling Systems

Continuous emission monitoring system shall be used accordance to SAE J 254(93) to analyse exhaust products emitted from gas engine as described in Figure 8.The continuous monitoring system shall consists of sample probe, sample lines, coolers, particulate filters, positive displacement pump, flow regulators and flow meters. All these equipment required for continuous emission monitoring system and should meet the specifications.

Figure 8: Example of Continous undiluted exhaust gas analysis system

(Source : SAE J254, 1993)

4.4.2.1 Sample Probe

The sample probe is the inlet to the system. It is recommended to be constructed of stainless steel tubing typically 6mm (0.25in) OD. It is usually part of fixture which adapts to the end of the exhaust stack of the engine. The probe should be located in the exhaust line at a distance of 1 to 3m form the exhaust manifold outlet flange or the outlet of the turbocharger. The most desirable probe location is parallel to the exhaust flow facing upstream. A valve should be located at near to the exhaust stack to allow purging of the sample probe with purified dry nitrogen or clean dry air.

4.4.2.2 Sample Line

The sample line carries the exhaust gas inducted into the sample probe to the condensers which are usually located close to the analysis system. This line is typically 6mm (0.25in) OD and should be made of stainless steel or Teflon (or equivalent). The length of sample line should be kept to a minimum since its length directly related to the delay time of the entire system. Hence, all tubes connecting the various components of the sampling system should be either stainless steel or Teflon and should be as short as possible.

4.4.2.3 Cooler

The cooler condenses and removes the water contained in in the exhaust gas sample. This cooling system is required because many analysers have strong response to water vapour and also to prevent condensation of water in the analysers. Two types of cooler that proved to be effective are ice-bath cooler and refrigerated water bath. Both of these utilize a cooling coil of 6mm (0.25in) OD [uncoiled length is approximately 3m (10ft)]. Usually the coolant filled with ice and water or a water glycol solution to maintain the temperature slightly above 0°C to prevent water freezing in the trap.

4.4.2.4 Sample Filter

Fluorocarbon coated glass fibre filters or fluorocarbon based membrane filters are required for certification purpose. All filter types have a 0.3µm DOP (dioctylphthalate) collection efficiency of at least 95% at a gas face velocity between 35cm/s and 80cm/s. The recommended minimum filter loading shall be 465µg/mm2 (0.5 mg/1075mm2) stain area for the single filter method. The most common filter sizes are given in Table 5. Additionally, diluted exhaust gas shall be sampled by a pair of filters placed in series (one primary and one back-up filter) during test sequence. The back-up filter shall be located no more than 100mm downstream of primary filter and shall not be in contact with the primary filter.

Table 5: Recommended minimum filter loading

(Source: ISO 8178-1, 1996)

4.4.2.5 Sample Pump

Pump is required to supply constant flow rate (typically 20L/min with pump inlet and outlet at atmospheric pressure) to pull the sample from the probe and then push the sample through the analyser. Individual pump can be used for each analyser or single pump also possible. To minimize hang-up, pump with stainless steel metal bellows or Teflon coated diaphragms should be used. The pump and motor should be mounted to eliminate mechanical vibration to the connecting sample lines and analysers because small mechanical vibration of the analyser may affect their output.

4.4.2.6 Flow Control and Measurement

By pass line is an optional way to increase sample flow rate which allows sample gas discharge to a waste system with the remaining 5L/min proceeding to the analyser. The bypass flow regulated by an adjustable needle valve (stainless steel) and monitored with a rotameter-type flowmeter with at least 10L/min capacity using a stainless steel or inert material float.

4.4.3 Emission Measurement and Analyser

The emission gasses to be measured shall be analysed using the instruments given in Table 6. Other measurement ranges can be employed if the accuracy in determining the component concentration is equivalent or better than given accuracy.

Table 6: Typical Ranges and Accuracy of Analytical System

(Source: ISO 8178-1, 1996 and EA-TGN-M21, 2010)

4.4.4 Instrument Operating Procedure

During testing follow the operating instructions as specified by the instrument manufacturer. Nevertheless, the following minimum requirements should be included accordance to SAE J177 (1995) and ISO 8178-1(1996E) standard.

System Response Time: The stabilized reading should give a deflection of at least 50% of full scale. To test response, introduce the NO span gas at the sample gas flow rate at the sample probe. Measure the time elapsed before a deflection of deflection of 90% response of stabilized reading is observed in recorder. The response time to the NO analyser of 20s or less is desired.

Calibration and Instrument checks: Calibration is required for initial start-up of the system and monthly for all equipment in use. Calibrate the instrument assembly and check the calibration curves using calibration gasses. The analyser calibration curve must be established by at least five points (excluding zero) spaced as uniformly as possible. The calibration curve must not differ by more than ±2% from the nominal value of each calibration point and by more than ±1% of full scale zero. The calibration gas flow rate should be same as sampling engine exhaust and minimum flow rate of 4 L/min is recommended. Figure 9, shows an example of typical NDIR analyser response curves to carbon monoxide and carbon dioxide.

Figure 9: Example of Typical NDIR Analyser Response Curves to

Carbon Monoxide and Carbon Dioxide

(Source: SAE J254, 1993)

Calibration Gases: The shelf life of all calibration gases shall be respected and expiry date of the calibration gases stated by the manufacturer shall be recorded. Table 7, shows the required pure gas with certain purity level and calibration and span gases with certain chemical composition that must be available for operation during engine emission testing.

Table 7: Required Calibration and Span Gases Composition

(Source: ISO 8178-1, 1996)

Pre-Test Check :

a. Warm up the analyser according to the recommendation of the manufacturer. If not specified a minimum of 2 hours is recommended for warming up the analysers.

b. Set zero and gain using purified dry air or nitrogen and the 100% range calibration gas

c. Recheck zero and repeat step (b), if necessary.

d. Calibrate the analyser with a minimum of four calibration gasses that are approximately 25, 50, 75 and 100% response of each range and establish calibration curve.

e. Note that, the calibration curve should fit the data points within ±1% full scale or ±2% of point whichever is less. If the discrepancy is greater and cannot be resolve, check calibration gases or consult with instrument manufacturer.

f. Check flow rate of calibration and span gases.

g. Check both refrigeration and condenser exit gas temperatures.

h. Check system for sample leaks by blocking off probe or probe end of sample line. If leaks exceeded 1% of total flow, rectify the problem immediately.

i. Check system response time prior to emission measurement.

4.4.5 Engine Emission Measurement Procedures

The following emission analysis procedure shall be conducted accordance to SAE J177 for emission measurements at steady state operating condition.

a. Install sample probe and attach instrument package to prepare for data cycles.

b. Start the engine and warm up under load until all temperatures and pressures have reached equilibrium.

c. Measure the emission gasses CO, CO2, O2, SO2 and NOX for 1 hour at every five minutes interval for each load once engine reached equilibrium condition. Note that, the results are considered valid if the repeatability of each reading at every 5 minutes is within 1%.

d. All emission readings should be recorded in data logger (if applicable) or manually and reported in final report.

e. The concentration of constituents in the exhaust are measured on dry basis in this procedure, thus convert the dry concentrations to wet basis accordance to SAE J177 (If necessary).

4.4.6 Emission Testing Frequency and Compliance

4.4.6.1

The emission testing shall be conducted during acceptance and annual test according to SAE and ISO standard for FiT application and must compliance with Malaysian Clean Air Standards (Stack Gas Emission Standards, 1978 and Air Quality Standards) or other relevant environmental act which will be notified by authority.

4.4.6.2

Nevertheless, supplementary monitoring using portable analyser recommended to be carried out for every 6 months to ensure NOx and CO emissions are within the appropriate limits. If the emission exceed the limits, then the engine need to be re-tune or consult the engine manufacturer to rectify the problem. The procedure for supplementary emission measurement shall be similar to continuous emission measurement system and the equipment need to be calibrated prior to emission measurement.

4.4.6.3

The plant owners allowed to use their existing continuous emission monitoring system during acceptance and annual test but the equipment must be calibrated according OEM recommendation and the calibration certificate must be verified by the OEM or any other certified calibration and measurement instrument laboratory. Meanwhile, the minimum requirement stated in section (4.4.4) must be included during instrument operating procedure and the calibration certificate must be reported in final report.

4.4.7 Safety and Health Precautions

a. This method may involve hazardous materials, operations, and equipment.

b. This guideline may not address all of the safety problems associated with its use. It is the responsibility of the user of this test method to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to performing this test method.

4.5 FUEL SAMPLING AND ANALYSI S

4.5.1 General guideline for sampling of biogas:

a. Frequency

Two samples shall be taken during the performance test and each samples need to be analysed three times and the average value taken as recorded measurement.

b. Sampling Location Point

Sample shall be collected as close to the gas engine prior to entering combustion chamber or as port provided for online analyser of power plant.

c. Sampling Bags

Tedlar or Multi-Layer Foil Bag shall be used for biogas sample collection and re-using the sampling bags strongly prohibited. The capacity of sampling bags should be around 5 to 10 litres.

d. Sample Preparation

The samples need to be collected separately if the analysis of fuel properties performed at different laboratory.

The samples need to be analysed within 8 hours of collection for greatest accuracy [3].

e. Fuel Analysis

All the biogas fuel properties listed in Table 8 shall be evaluated at SAMM accredited laboratory accordance to standard test methods described in section 4.5.3.

Table 8: Biogas Fuel Properties

f. Test report

Sampling test report shall describe the followings:

All biogas property results

List of equipment and Methodology used for property analysis

SAMM accreditation Certificate

g. Sample labelling

Sampling container shall describe the followings:

Name and designation of sampler

Type of fuel

Test number, test date and time

Sample collection number, date and time

Sample processed date and time

4.5.2 Reference Procedure for Biogas Sample Collection

The following steps shall be followed for biogas sample collection prior to performance test.

a. Connect a short piece of clean PVC tubing to the barbed screw-lock valve of Tedlar bag or multi-layer foil sampling bag. The sampling bag comes with various types of valve thus end user free to choose any type of valve which is suitable for their application.

Figure 10: Sample of Barbed Screw Lock

b. Then connect the PVC tubing to biogas sample collection valve (located close to engine prior to entering combustion chamber) and ensure the PVC tubing connected well at both end no leaking during sample collection.

c. Turn on biogas line then unscrew valve to fill bag with biogas. Then tighten the sampling bag valve before bag becomes over pressurized and turn off the gas line. Notes: The sampling bag should not be filled to more than 80% of their maximum value.

d. Empty the bag completely and repeat the steps (a to c) for twice for acclimatization purpose.

e. After the bag has been purged with biogas to be sampled 3 times, reconnect the sampling bag with PVC tubing and turn on gas line. Then fill the sample bag with biogas and close valve. Subsequently, turn off gas line and disconnect bag from gas line.

f. Transport the biogas sample to respective laboratory for property analysis and ensure the sample analysed within 8 hours.

4.5.2.1 Safety and Health Considerations

This guideline does not address all of the safety concerns associated with its use. It is the responsibility of the user of this guideline to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Refer section 3.4 for recommended safety concerns in biogas plant

4.5.3 Reference procedure for Sample Analysis

a) The biogas fuel properties as listed in Table 9, is mandatory for acceptance test. However, for annual test the properties will be determined in accordance to the acceptance test results. If any of the property is found to be negligible during acceptance test then that particular composition can be avoided during annual test except for landfills biogas.

b) Therefore, all the properties listed in Table 9, will be analysed for acceptance and annual test for biogas obtained from landfills.

c) The followings are recommended standard test method to be used for fuel sample property analysis. However, other equivalent international standards are accepted for fuel property analysis but have to be justified in the test report.

Table 9: Test Methods for Biogas Fuel Properties

4.6 Calibration of Test Instrumentations

a) All instruments used for biogas fuel properties measurement must be calibrated before the test. The equipment/ and measuring instruments calibrations report must be included in the test report. All calibrations must be performed by SAMM Accredited Laboratory, in compliance to the ISO/IEC 17025 or its equivalent.

b) All instruments used for data measurement must be calibrated in accordance to OEM recommendation. However, if OEM doesn’t provide calibration intervals for any instruments thereby the instruments shall be calibrated annually by certified calibration and measurement laboratory such as SIRIM.

PART 5 REFERENCE TEST CONDITIONS AND CORRECTIONS

This section contains reference air and fuel supply test conditions and specifications, recommended test ranges and applicability of the power correction procedures.

5.1 Reference Atmospheric Condition

For the purpose of determining the power and fuel consumption of an engine, the following standard reference shall be used accordance to SAE J1349, ISO 15550:2002 (E) and ISO 3046-1(2002). The test should be conducted accordingly and no modification to the composition of the intake air is permitted. Table 10, defines reference atmospheric condition and test ranges for which correction factors are valid.

Table 10: Reference Atmospheric Condition

(Source: ISO 15550, 2002)

5.2 Atmospheric Correction Factor (fa)

This correction factor indicates the effects of environmental conditions such as pressure, temperature and humidity on the air drawn in by the engine and it will differs according to the type of engine. The atmospheric correction factor shall be calculated from equation (1), (2) and (3).

a. Naturally aspirated engine and mechanically pressure charged engine:

b. Turbocharged engines with charge air cooling by air to liquid charge air cooler :

c. Turbocharged engines with charge air cooling by air to liquid charge air cooler

5.3 Alternative Fuels

The international standard that referred for this guideline which is SAE J1349, ISO 15550:2002 and ISO 3046-1 only have reference values for standard gasoline (natural gas) and diesel. Therefore, reference values for alternative fuel for SI and CI engine for liquid and gaseous are not presented in this document. In that case, when alternative fuels are used for the net power engine test, no corrections to reference fuel conditions shall be made. However, the energy content (Energy Input - Lower Heating Value) of the alternative fuel shall be defined prior to testing and should comply with engine manufacturer specifications. Meanwhile, the net power obtained at power meter will be considered as total net power generated by the engine due to combustion.

5.4 Power Correction Factor

The performance of SI and CI engine is affected by the density of the inlet combustion air and the characteristics of the test fuel. Thus, it’s strongly recommended to conduct the test at the standard reference conditions. Whenever, the reference conditions not possible then power correction factors should be applied to the observed net power and torque to account for differences between reference air and fuel conditions and those at which the test data were acquired.

5.4.1

All power and torque correction procedures for atmospheric air based on the conditions of the engine inlet air supply immediately prior to the entrance into the engine air induction system. During the test, the ambient air condition must comply with reference air condition as defined in Table 10. Air supply system that provide tuning or pressure charging in violation of the intent of this procedure are prohibited.

5.4.2

Any engine SI or CI where the power output is automatically controlled to compensate for changes in one or more of the listed inlet air condition then no correction for that test parameter shall be made. For example, boosted engine with absolute pressure control shall not be corrected for ambient barometric pressure.

5.4.3

The magnitude of the power correction for test run at non-standard conditions should not exceed 3% for inlet air condition. If the correction factor exceeds this value, it shall be noted as non-standard test accordance to SAE J1349.

5.5 Method of Power Correction

This power correction method has been verified by tests on representative number of pre-test engines speeds of 2000 min-1 and above. This power correction method shall be used to calculate the power at the standard air reference condition as defined in Table 10. The purpose of power correction is the observed/measured power during test shall be multiplied by a factor as follows:

a. For Spark Ignition (SI) Engine

b. For Compression Ignition (CI) Engine

c. Correction factor (αa) for naturally aspirated and pressure charged spark ignition engines (with or without charge air cooling)

Equation (6) is only applicable if: 0.96 ≤ αa ≤ 1.06, if these limits are exceeded, the corrected power value obtained shall be given and the test conditions (temperature and pressure) precisely stated in the report.

Equation (6) applies to engine with carburettor and other engine where the fuel management system is designed to maintain a relatively constant F/A ratio as ambient change. For other engines refer section (5.6).

d. Correction factor (αc) for compression ignition engine :

Where, fa = Atmospheric factor (Refer 5.2)

fm = Engine factor (Refer 5.5e)

e. Engine Factor (fm)

Factor (fm), is dependent on the type of engine and the trapped air/fuel ratio corresponding to the fuel setting. The engine factor (fm), is a function the corrected fuel delivery (qc), shall be calculated from equation (8). Since there is no correction factor shall be made for alternative fuel, thus actual/measured fuel flow rate can be used for the following equation to determine the engine factor.

Where,

Where, q = Fuel delivery parameter in milligram per cycle per litre (mg/l.cyle)

and equal to equation (9)

Where Z = 120,000 (4 Stroke) and 60,000 (2 Stroke)

rr = Equal to 1 for (Naturally aspirated engine) and for two stage

turbo charging (r) is the overall pressure ratio.

Equation (8) is valid for the following range (qc)

37.2 ≤ qc ≤ 65 ; If (qc) lower than 37.2 then (fm) = 0.2 or If (qc) higher than 65 then (fm) = 1.2

5.6 Other Types of Engine

For engine not covered by section (5.5c and 5.5d), a correction factor equal to 1 shall be applied when the ambient air density does not vary more than ±2 % from the density at standard reference condition. If the ambient density fall beyond the limit ±2 % then no correction factor shall be applied but the test condition shall be stated in in the test report.

PART 6 TEST DATA AND RESULT ANALYSIS

6.1 Reciprocating Gas Engine

In reciprocating gas engine, Energy Input, Eindefined as the chemical heat in the fuel (Lower Heating Value (LHV) of the fuel as determined from SAMM accredited laboratory. For gas engine there is no additional heat energy added for the system in fact heat released to ambient thorough conduction and convection due to combustion process. Figure 11, shows the energy balance for the reciprocating gas engine which is integrated with power generator. The heat released to the ambient and energy loss due to mechanical friction during operation defined as Energy loss, (Eloss). Meanwhile, the net energy generated from generator defined as Energy Output (Eout) where the net energy will be measured at power.

Figure 11: Energy Balance for a Reciprocating Gas Engine

The heat balance for reciprocating engine system is given below:

6.2 Chemical Energy Input or Heat Consumption Rate

Total Chemical Energy Input, EHF = Fuel Heat Value (LHV) x Volume flow rate of fuel

Where,

EHF= Total chemical energy input (kJ/hr )

Hf = Lower Heating value of Fuel, obtained from laboratory analysis (kJ/kg)

Vf = Volume flow Rate of gaseous fuel (m3/hr)

ρfuel = Density of fuel at 15°C, Obtained from laboratory analysis (kg/m3)

6.3 Energy Output and Losses or Heat Rate Calculations

For this analysis, the energy output measured from power meter and the losses mainly generated due heat loss to surrounding and mechanical friction during operation. These losses are impractical to measure at site during operation. Thus, these values, ELossshall be provided by manufacturer. Moreover, energy loss occur in generator also shall be provided by the manufacturer.

Thus,

Where,

Total Energy Loss, ELOSS = Sum of all energy loss in the system (Heat from engine,

Friction, losses in power generator)

The net Energy, ENET = The energy generated by the gas engine after all the

losses have been deducted

The Total Energy, ETotal = Total energy produced in the system

6.3b.Heat Rate Calculations

The heat rate can be calculated using following equation:

Where,

QS = Heat Rate (kJ/kWhr)

EHF = Total chemical energy input (kJ/hr)

ENET =The net electrical energy generated by the gas engine after all losses have

been deducted (kW).

6.4 Thermal efficiency Calculation for Reciprocating Engine

Thermal efficiency of reciprocating engine can be determined using the following equation.

Where,

ηEff = Thermal efficiency based on net electrical power

EHF = Total chemical energy input

ENet =The net electrical energy generated by the gas engine after all losses have

been deducted.

ENet Corr = Corrected net electrical power

If the test conducted at non-standard atmospheric condition then power correction factor shall be applied for net energy generated (ENet). Then the thermal efficiency will be obtained using (ENet corr) as shown in Eq (16).

Where,

αa = Power correction factor (Use αc for compression ignition engine)

Thus,

6.5 Air Fuel Ratio and Equivalence Ratio

Air fuel ratio is an important parameter to obtain desired combustion with less emission pollutants. Thus, the following equation can be deployed to obtain A/F ratio of biogas combustion in gas engine.

a. Combustion of Biogas

b. The value of (x) can be calculated from the following equation (Eqn.19) :

Where,

For Stoichiometric combustion: % O2 is equal to zero and thus by substituting O2 value into Eqn.19,( x = 0.775)

c. Thus, the Stoichiometric of A/F ration of biogas can be calculated from the following equation ( Eqn.20)

Now, the actual A/F ratio can be determine from measured data of combustion air flow and fuel flow during the test.

d. The actual air flow ratio can be determine using equation below :

e. Equivalent ratio can be calculated from the following equation :

6.6 Input Data Required for Reciprocating Engine Performance

PART 7 PERFORMANCE RESULTS ASSESSMENT’S

Based on the results obtained during performance evaluation, results assessment as listed in Table 11 shall be made:

Table 11: Results Assessments

It is also desirable but not mandatory for a performance curve showing plant output data throughout the test to be plotted for all test runs.

PART 8 LIST OF REFERENCES

[1] Parajuli P., (2011),“ Biogas Measurement Techniques and the Associated Errors”, Department of Biological and Environmental Science’ 2011.

[2] Bothi K.L., (2007), “Characterization of Biogas from Anaerobically Digested Dairy Waste for Energy Use”, Faculty of Graduate School of Cornell University, 2007.

[3] Wellinger A., Person M., Johnsson O.,(2006), “ Biogas Upgrading to Vehicle Fuel Standards and Grid Injection”, IEA Bioenergy 2006.

[4] BEE Code for Co-Generation. Indian Renewable Energy Development Agency (2006)

[5] ISO 8178-1, Reciprocating Internal Combustion Engines – Exhaust Emission - Measurement, Part-1: Test-Bed Measurement of gaseous and particulate exhaust emission at site.1st Edition, (1996).

[6] ISO 3046-1, Reciprocating Internal Combustion Engines, Performance – Declaration of Power, Fuel and Lubricating Oil Consumptions, and Test Methods – Additional Requirements for Engines for General Use, 5th Edition, (2002).

[7] ISO 15550, Internal Combustion Engines – Determination and Method for The Measurement of Engine Power General Requirements, 1st Edition, 2002.

[8] SAE J1349, Engine Power Test Code – Spark Ignition and Compression Ignition – As Installed Net Power Rating, 2011.

[9] SAE J1515, Impact of Alternative Fuels on Engine Test and Reporting Procedures, 1988.

[10] SAE J177, Measurement of Carbon Dioxide, and Oxides of Nitrogen in Diesel Exhaust, 1995.

[11] SAE J1003, Diesel Engine Emission Measurement Procedure, 1995.

[12] SAE J254, Instrumentation and Techniques for Exhaust Gas Emissions Measurement, 1993.

[13] IEC 60567,Oil-Filled Electrical Equipment-Sampling of Gasses and Oil for Analysis of Free and Dissolved Gases- Guidance, 3rd Edition, 2005.

[14] Environment Agency, Guidance for Monitoring Landfill Gas Engine Emissions. Online: www.enviornment-agency.goc.uk. (2008).

[15] Rosaler R.C., 2002, “Standard Handbook of Plant Engineering”, 2nd Edition, (2002).

[16] PTC19.5 (R2004) - Supplementary Code on Instruments & Apparatus for Flow Measurements

[17] PTC 19.6 Electrical Measurements In Power Circuits Instruments And Apparatus

[18] PTC19.2 - (R1998) - Supplementary Code on Instruments & Apparatus for Pressure Measurements.

[19] ASME PTC 19.3 (R1998) - Supplementary Code on Instruments & Apparatus for Temperature Measurement.

[20] ASME PTC 19.10 Supplementary Code on Instruments & Apparatus - Flue and Exhaust Gas Analyses

[21] Biomass Energy Data Book 2011.

[22] Renewable Energy (Technical and Operational Requirements) Rules 2011.

[23] Renewable Energy (Feed in Approval and Feed in Tarif Rate), (Amendment), Rules 2013.

[24] Environment Agency (EA), 2010, “Technical Guidance Note-M21 (monitoring), A Procedure to Use An Alternative Method for Measuring Emissions of Sulphur Dioxide, Using Instrumental Techniques”, Version 1.1, 2010.

PART 9 LIST OF APPENDIX

Appendix 1: List of Parameters and Permissible Deviation

Appendix 2: Standard Production Equipment

Appendix 3: Determination of Water Vapor Pressure

Appendix 3: Determination of Water Vapor Pressure (Continue)

Appendix 4: Determination of Dry Air Pressure Ratio Values

Appendix 4: Determination of Dry Air Pressure Ratio Values

Appendix 5: Approximate Space Envelope for Gas Engine Generators